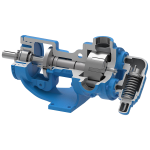

Description

Features

- Max. Capacity: to 500m3/h

- Max. Pressure: to 16 bar

Overall dimensions and performances are in accordance to standards ISO 2858/DIN 24256. Materials of construction are numerous, from cast iron to hastelloys.

High hydraulic efficiencies and low NPSH requirements.

Shaft sealing by packed stuffing box, single or double mechanical seals (ISO 3069/UNI EN 12756) with every installation option per API requirements.

Pump casing and seal housing can be provided with heating or cooling chambers, as needed.

Units up to 30 kW size can be close coupled, with the addition of a support lantern, to motors with B5 flange. This monoblock design offers great alignment advantages, simplicity of assembly and guarantee of perfect alignment even after transportation.

From the TCH series have derived series TCT, TCA and TCD that are designed for very specific pumping applications; all these series utilise many common components.

Mechanical Seal

TCH pump series and derived series can be fitted with any type of mechanical seal that is unified to the ISO 3069/UNI EN 12756 standards. Single mechanical seals, double mechanical seals in tandem or back to back arrangements can be fitted with flushing systems to API standards. The pump bearing frame offers versatility and plenty of space to also allow fitting special types of mechanical seals that may not have unified dimensions, i.e.: cartridge type seals

Materials

TCH pumps have many material solutions, starting from cast iron and stainless steel iron up to SAF and Hastelloy.

Special Executions

ATEX (ATmosphere EXplosive)

MOCA (Food Industry)

Pump

Pump Viking gear pump (USA)

Viking gear pump (USA) Viking lobe pump (USA)

Viking lobe pump (USA) Corken vane pump (USA)

Corken vane pump (USA) Versa Matic diaphragm pump (USA)

Versa Matic diaphragm pump (USA) Travaini centrifugal pump (Italy)

Travaini centrifugal pump (Italy) Travaini vacuum pump (Italy)

Travaini vacuum pump (Italy) Atlas Copco vacuum pump (Belgium)

Atlas Copco vacuum pump (Belgium) Flux drum pump (Germany)

Flux drum pump (Germany) Iwaki metering pump (Japan)

Iwaki metering pump (Japan) Iwaki magnetic pump (Japan)

Iwaki magnetic pump (Japan) Ebara centrifugal pump (Japan)

Ebara centrifugal pump (Japan) Tsurumi submersible pump (Japan)

Tsurumi submersible pump (Japan) Ebara submersible pump (Japan)

Ebara submersible pump (Japan) Tsurumi blower (Japan)

Tsurumi blower (Japan) Travaini blower (Italy)

Travaini blower (Italy) Air/Gas Compressor

Air/Gas Compressor Atlas Copco - Ceccato air compressor (Belgium)

Atlas Copco - Ceccato air compressor (Belgium) Corken gas compressor (USA)

Corken gas compressor (USA) Loading arm

Loading arm Flexible hose

Flexible hose Flow meter

Flow meter Flux flow meter (Germany)

Flux flow meter (Germany) Instruments

Instruments Motor - Gear box

Motor - Gear box Heat exchanger

Heat exchanger Valve

Valve Corken valve (USA)

Corken valve (USA) Others

Others Ball vavle

Ball vavle Check valve

Check valve Gate valve

Gate valve Globe valves

Globe valves Needle valves

Needle valves Safety valves

Safety valves Butterfly valves

Butterfly valves Solenoid valves

Solenoid valves Pressure reducing valves

Pressure reducing valves Diaphragm valves

Diaphragm valves Bellow sealed valves

Bellow sealed valves Foot valves

Foot valves Control valve

Control valve Stop valves

Stop valves Float valves

Float valves Sanitary valves

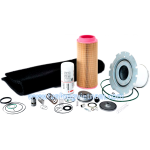

Sanitary valves Spare parts

Spare parts Air compressor

Air compressor Diaphragm pump

Diaphragm pump