Showing 73–96 of 315 results

-

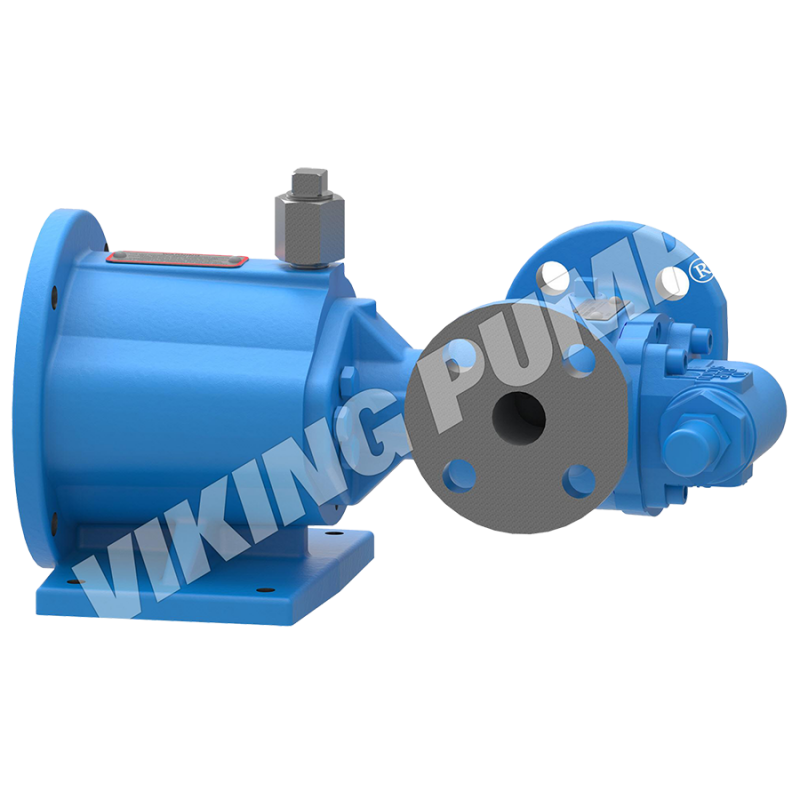

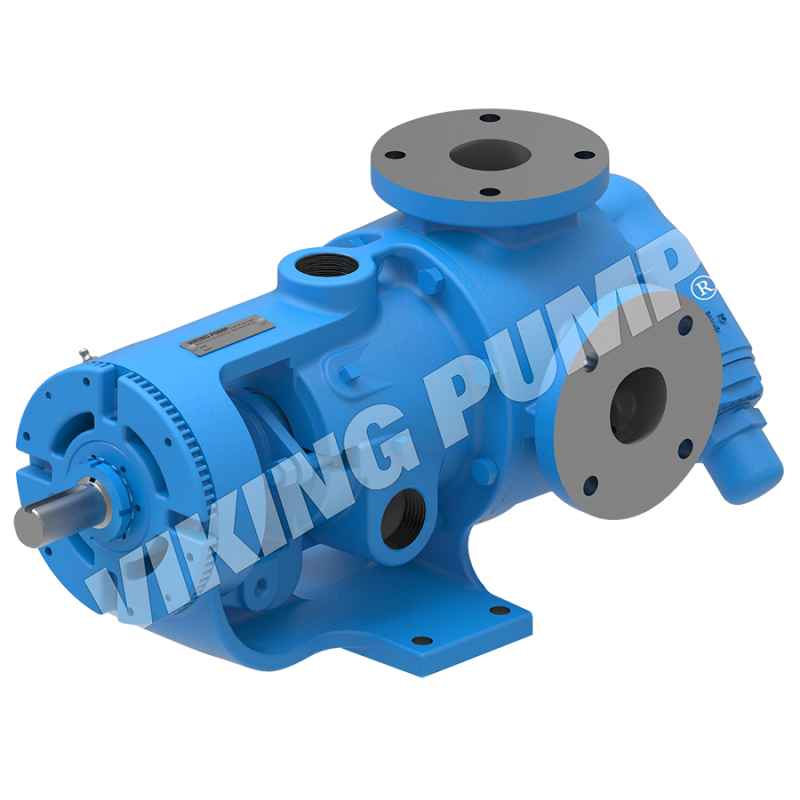

Viking – 4223A

Pumps are designed for a broad range of applications, from thin to thick, requiring continuous duty at pressures up to 200 PSI (14 Bar). Even higher pressures are possible with high fluid viscosities at reduced operating speeds (consult factory). They are also capable of operating under suction lift conditions and operate equally well in either direction.

The Universal Product Line has the broadest range of sealing options of all pumps built by Viking. The stuffing box on all sizes accepts packing, numerous component single mechanical seals, or a wide variety of cartridge seals.

The Universal Product Line is Viking Pump’s most versatile line of internal gear pumps due to the availability of many design and material options.

-

Viking – LVP

The LVP Series™ is designed for thin, corrosive industrial liquids, flammable liquids which require corrosion protection and applications where pressures or vacuum requirements exceed other pumps’ capabilities. Vanes extend from slots on the rotor, sweeping liquid through a cam-shaped cavity. They offer the benefit of very low slip and high mechanical efficiency.

-

Viking – REVOLUTION

TYPICAL APPLICATIONS: Pharmaceutical I Personal Care I Foods I Beverage I Dairy I Confectionary I Chemical

-

Viking – 893

893 Series pumps are designed to provide positive displacement pumping capability in those situations that require the highest assurance of liquid containment. These mag drive pumps provide for the safe, trouble-free transfer of hazardous, EPA-regulated fluids without electronic monitoring as required with mechanical face-type shaft seals. Hard-to-seal liquids are also easily handled with the Viking Mag Drive which eliminates the high cost of mechanical seal replacement and repair. A variety of coupling sizes are available for flow requirements to 75 GPM. The torquecarrying ability of high-strength magnets allows pumps to be coupled with gear reducers for slow-speed handling of viscous liquids. The self-priming positive-displacement

pumping principle provides low-shear, non-pulsing flow. Internal gear pumps are available in stainless steel, steel, and cast iron construction. -

Viking – 895

895 Series pumps are designed to provide positive displacement pumping capability in those situations that require the highest assurance of liquid containment. These mag drive pumps provide for the safe, trouble-free transfer of hazardous, EPA-regulated fluids without electronic monitoring as required with mechanical face-type shaft seals. Hard-to-seal liquids are also easily handled with the Viking Mag Drive which eliminates the high cost of mechanical seal replacement and repair. A variety of coupling sizes are available for flow requirements to 75 GPM. The torquecarrying ability of high-strength magnets allows pumps to be coupled with gear reducers for slow-speed handling of viscous liquids. The self-priming positive-displacement

pumping principle provides low-shear, non-pulsing flow. Internal gear pumps are available in stainless steel, steel, and cast iron construction. -

Viking – 897

897 Series pumps are designed to provide positive displacement pumping capability in those situations that require the highest assurance of liquid containment. These mag drive pumps provide for the safe, trouble-free transfer of hazardous, EPA-regulated fluids without electronic monitoring as required with mechanical face-type shaft seals. Hard-to-seal liquids are also easily handled with the Viking Mag Drive which eliminates the high cost of mechanical seal replacement and repair. A variety of coupling sizes are available for flow requirements to 75 GPM. The torquecarrying ability of high-strength magnets allows pumps to be coupled with gear reducers for slow-speed handling of viscous liquids. The self-priming positive-displacement

pumping principle provides low-shear, non-pulsing flow. Internal gear pumps are available in stainless steel, steel, and cast iron construction. -

Viking – 432

Viking’s Motor Speed Product Line internal gear pumps are extremely well suited for light, medium and intermittent service handling a variety of liquids. The smaller sizes C, F, FH are constructed for heavier duty service. Mechanical seal equipped pump models in sizes C, F, FH, G, H, HL are available with Underwriters label for handling fuel oil. Model numbers for these pumps must be designated by a suffix -X.

UL listed models can be equipped with integral relief valve. Viking’s unique and unusually simple pump construction makes it adaptable to many diversified installations. The pumps possess excellent vacuum characteristics and will operate and prime at suction lifts up to 25 feet, depending upon the vaporization point of volatile liquids. Because of the cushioned action in providing a continuous and steady stream of liquid without splashing, pounding, foaming or churning, the Viking pump is adaptable to an unlimited number of industrial applications

-

Viking – 456

The 456 Motor Mounted units answer the need for more compact, lighter weight equipment. They use the Series 456 hub type pumps with valves in casings and are mounted to modified NEMA “C” flange motors. Units are available with ¼, ⅓, ½ or ¾ HP, 1 ph, 1200 RPM or 1800 RPM, special shaft, TEFC or explosion proof motors. All sizes use the mounting flange bracket with pump connected to motor through a coupling. The pump can be turned on the bracket to any position desired.

-

Viking – 75

For compactness, less weight and simplicity of mounting, Viking’s line of close-coupled pumps are ideal for direct connecting to other pieces of equipment. The positive, smooth delivery of these pumps makes them preferred for many types of applications including filtering, circulating, transferring, lubricating or booster service.

-

Viking – 475

This advanced design is unique in its field for it permits use of STANDARD, unmodified NEMA C flange ball bearing motors.

-

Viking – 227A

Pumps are designed for a broad range of applications, from thin to thick, requiring continuous duty at pressures up to 200 PSI (14 Bar). Even higher pressures are possible with high fluid viscosities at reduced operating speeds (consult factory). They are also capable of operating under suction lift conditions and operate equally well in either direction.

The Universal Product Line has the broadest range of sealing options of all pumps built by Viking. The stuffing box on all sizes accepts packing, numerous component single mechanical seals, or a wide variety of cartridge seals.

The Universal Product Line is Viking Pump’s most versatile line of internal gear pumps due to the availability of many design and material options

-

Viking – TRA®10

GEAR BOX: Powder-coated standard I 304 stainless steel optional

-

Viking – TRA®20

GEAR BOX: Powder-coated standard I 304 stainless steel optional

-

Viking – 1227A

Viking Pump is the leader in internal gear innovation and the latest development is the O-Pro™ Seal technology. The NEW Universal Seal Product Line comes with the O-Pro Guard Seal factory installed. The Universal Product Line combines the tested reliability of the Universal pump & O-rings to create a robust seal and lubrication chamber, all in one.

-

Viking – STERILOBE

Standard bi-wing rotors offer application flexibility & good solids handling capabilities

Multi-lobe rotors reduce shear & pulsation effect; ideal for sensitive media

Innovative cusps with reliefs allow for easier cleaning and self draining with improved efficiency -

Viking – CLASSIC+

Modular pump design promotes easy disassembly for COP (Clean Out of Place) & CIP (Clean In Place)

-

Viking – 4227A

Pumps are designed for a broad range of applications, from thin to thick, requiring continuous duty at pressures up to 200 PSI (14 Bar). Even higher pressures are possible with high fluid viscosities at reduced operating speeds (consult factory). They are also capable of operating under suction lift conditions and operate equally well in either direction.

The Universal Product Line has the broadest range of sealing options of all pumps built by Viking. The stuffing box on all sizes accepts packing, numerous component single mechanical seals, or a wide variety of cartridge seals.

The Universal Product Line is Viking Pump’s most versatile line of internal gear pumps due to the availability of many design and material options.

-

Viking – TR-IS

316L stainless steel construction certified for 3A and in compliance with EHEDG standards

-

Viking – RTP

Designed specifically for the hygienic stainless steel road tanker industry, the RTP outperforms the competition by providing higher capacity, higher pressure and unmatched efficiency. The RTP can also reduce loading and unloading time by over 30%.

This increased performance, along with advanced durability, application flexibility, ease of installation and ease of maintenance provide a complete solution for your hygienic tanker needs.

-

Viking – TR-C

TR-C and other “C-Series” pumps can be converted to TR-C+ with a simple kit

-

Viking – 4124B

The 4124B series heavy duty internal gear pumps have Behind the Rotor dynamic shaft seals. By locating the mechanical seal immediately behind the rotor, this prevents the shaft and bracket bushing from coming into contact with the liquid.

-

Viking – RTPE

For too long, cast iron pumps have compromised the integrity of chemicals carried in stainless steel road tankers. Designed specifically for the chemical transport industry, the RTPe stainless steel pump delivers that essential missing component. Better yet, it provides a cost-effective solution to this problem, while still outperforming the competition in both speed and reliability.

Based on the industry-leading hygienic RTP, the RTPe incorporates all of the features your chemical tanker needs, while eliminating those that it does not.

Protect your investment and make your chemical transport business even stronger. The RTPe is the essential component to complete your chemical tanker system.

-

Viking – 4223AX

4223AX & 4323AX Series foot-mounted internal gear pumps are designed and manufactured to comply fully with the current version of American Petroleum Institute’s design standard for positive displacement pumps, API 676. Applications include oil and gas and petrochemical industries where exceptional reliability is required.

-

Viking – 4224B

The Universal Product Line has the broadest range of sealing options of all pumps built by Viking. The stuffing box on all sizes accepts packing, numerous component single mechanical seals, or a wide variety of cartridge seals.

The Universal Product Line is Viking Pump’s most versatile line of internal gear pumps due to the availability of many design and material options

Pump

Pump Viking gear pump (USA)

Viking gear pump (USA) Viking lobe pump (USA)

Viking lobe pump (USA) Corken vane pump (USA)

Corken vane pump (USA) Versa Matic diaphragm pump (USA)

Versa Matic diaphragm pump (USA) Travaini centrifugal pump (Italy)

Travaini centrifugal pump (Italy) Travaini vacuum pump (Italy)

Travaini vacuum pump (Italy) Atlas Copco vacuum pump (Belgium)

Atlas Copco vacuum pump (Belgium) Flux drum pump (Germany)

Flux drum pump (Germany) Iwaki metering pump (Japan)

Iwaki metering pump (Japan) Iwaki magnetic pump (Japan)

Iwaki magnetic pump (Japan) Ebara centrifugal pump (Japan)

Ebara centrifugal pump (Japan) Tsurumi submersible pump (Japan)

Tsurumi submersible pump (Japan) Ebara submersible pump (Japan)

Ebara submersible pump (Japan) Roto progressive cavity pump (India)

Roto progressive cavity pump (India) Tsurumi blower (Japan)

Tsurumi blower (Japan) Travaini blower (Italy)

Travaini blower (Italy) Air/Gas Compressor

Air/Gas Compressor Atlas Copco - Ceccato air compressor (Belgium)

Atlas Copco - Ceccato air compressor (Belgium) Corken gas compressor (USA)

Corken gas compressor (USA) Loading arm

Loading arm Flexible hose

Flexible hose Flow meter

Flow meter ABB flow meter (Switzerland)

ABB flow meter (Switzerland) Flux flow meter (Germany)

Flux flow meter (Germany) Motor - Gear box

Motor - Gear box Cemp motor (Italy)

Cemp motor (Italy) Jie gearmotor (China)

Jie gearmotor (China) Heat exchanger

Heat exchanger Valve

Valve Kitz valve (Japan)

Kitz valve (Japan) Others

Others Ball vavle

Ball vavle Check valve

Check valve Gate valve

Gate valve Globe valves

Globe valves Needle valves

Needle valves Safety valves

Safety valves Butterfly valves

Butterfly valves Solenoid valves

Solenoid valves Pressure reducing valves

Pressure reducing valves Diaphragm valves

Diaphragm valves Bellow sealed valves

Bellow sealed valves Foot valves

Foot valves Control valve

Control valve Stop valves

Stop valves Float valves

Float valves Sanitary valves

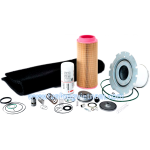

Sanitary valves Spare parts

Spare parts Air compressor

Air compressor Diaphragm pump

Diaphragm pump